Free Shipping

Free shipping on orders over 1999.

Support

24x7 Support

Secure Checkout

We ensure 100% Payment Secure.

- Efficiency: Patented treatment enhances cutting efficiency, saving time.

- Precision: Uniform taper design ensures precise canal shaping.

- Flexibility: Easily navigates curved canals for versatile use.

- Safety: High resistance to cyclic fatigue minimizes file separation risks.

- User-Friendly: Tip indicators and laser markings simplify use.

- Versatility: Comes in various lengths and sizes for diverse canal types.

- Convenience: Sold in packs of 6 files for multiple procedures.

- Optimal Conditions: Recommended speed and torque settings ensure effectiveness.

- Patient Comfort: Efficient procedures contribute to better patient comfort.

Description

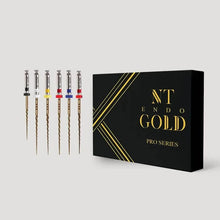

NT Gold Pro NiTi Rotary Files are advanced dental instruments designed for performing root canal treatments with exceptional precision and efficiency. Crafted by amalgamating American NiTi wire with European precision milling technology, these files exhibit unparalleled performance attributes. Their patented thermal treatment enhances cutting efficiency, while their flexibility allows for easy negotiation of curved canals. Additionally, these files demonstrate remarkable resistance to cyclic fatigue, ensuring safety throughout the procedure. Featuring a uniform taper design and a convex triangular cross-section with sharp cutting edges, these files provide consistent, precise, and efficient canal shaping. Their passive safety tip design minimizes the risk of procedural errors. Unique tip size and taper indicators on the shank, along with precise laser markings for working length indication, simplify the workflow for clinicians. Available in various lengths and sizes, these files cater to diverse canal dimensions and types. With a recommended operating speed of 300 RPM and a torque range of 1.5-2.5 NCm, these rotary files are indispensable tools in modern endodontic practice, ensuring optimal outcomes and patient comfort during root canal procedures.

Key Specifications

- Material: American NiTi wire with European precision milling technology

- Patented Thermal Treatment: Enhances cutting efficiency

- Flexibility: Allows for negotiation of curved canals

- Cyclic Fatigue Resistance: Ensures safety during use

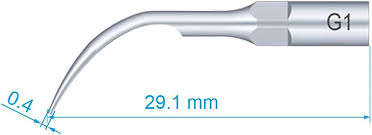

- Uniform Taper Design: Consistent and precise canal shaping

- Cross-Section: Convex triangular with sharp cutting edges

- Safety Tip Design: Reduces procedural errors

- Lengths Available: 21mm, 25mm, 30mm

- Sizes Available: 19/08, 15/04, 20/04, 20/06, 25/04, 30/04, 35/04

- Speed: Recommended at 300 RPM

- Torque: Recommended range of 1.5-2.5 NCm

Preparation:

- Access Cavity: Begin by preparing the access cavity and locating the canal orifice using standard procedures.

Exploration and Initial Shaping:

- Initial Exploration: Start the procedure by exploring the canal using a #8 or #10 K-File to remove any obstructions and gain initial access.

- Coronal Flaring: Use the 19/08 Orifice Opener to perform coronal flaring, focusing on the coronal third of the canal. This step facilitates better access to the canal.

- Glide Path Creation: Create a glide path using a #15 handfile. This step prepares the canal for the subsequent use of rotary files.

Working Length Determination:

- Working Length: Determine the working length accurately using an Apex Locator or Radiograph. This step is crucial for precise canal shaping.

Enhanced Glide Path:

- Glide Path Enhancement: Continue enhancing the glide path using a 15/04 NT File. Progress the file until it reaches the measured working length, adhering to the recommended speed and torque settings.

- Irrigation and Recapitulation: Ensure proper irrigation of the canal and recapitulate with a K-File between two rotary files. This step helps maintain cleanliness and safety.

Canal Shaping:

- Initial Canal Preparation: Use a 20/04 NT file for the initial canal preparation, following the recommended settings. This step allows for the effective shaping of the canal.

- Final Canal Preparation: Complete the final canal preparation using a larger size, such as 25/04, 30/04, 25/06, or greater, depending on the specific canal morphology. This step ensures proper shaping and cleaning of the canal.